| ENCODERS |

|---|

A variety of encoders are available from Velmex that deliver an ultra-precise reading of the position of the carriage (slider) of various Velmex stages. Encoders offered include magnetic, inductive or rotary modes.

tab=0Overviewtab=1Featurestab=2Model / Seriestab=3Specificationstab=4Options / Accessoriestab=5Downloadstab=6Examplestab=7Troubleshooting / FAQs

Encoders for High Resolution Position Readouts

Velmex offers linear inductive and magnetic encoders along with rotary encoders for use in measuring position on Velmex stages.

Mounted directly on the slider (carriage), the encoders deliver a true and accurate reading of the slider's movement and position. The Ultra-Precision Measurement System's direct pin-point readings also reduce inaccuracies in the lead screw or caused by backlash. Magnetic and inductive encoder alternatives today have significant advantages over glass scale technology. Inductive and magnetic encoders are more durable, use non-contact sensing, integrate better, and offer high accuracy in combination with Velmex UniSlide® and BiSlide® Assemblies. Rotary encoders are used both on Velmex Rotary Tables and on XSlide™ Assemblies.

Encoder Features

Various encoders have advantages in specific applications. Velmex's Ultra-Precision Measurement System offers a variety of encoders to address our customers' various application needs and to complement the specific assembly it can be used on.

| Encoder | Advantages | Disadvantages |

|---|---|---|

| Inductive Scale | • Accuracy equal to glass scale encoders • Impervious to dirt and liquids • Compact • Any travel length possible |

• Costs more than magnetic encoders |

| Magnetic Scale | • Impervious to dirt and liquids • Compact • Any travel length possible • Less cost especially in longer lengths |

• Less accuracy versus inductive or glass scale encoders |

| Rotary Encoders | • Cost effective • Ideal for rotational distance on a lead screw or motor shaft |

• More susceptible to dirt and external noise. |

Rotary Encoders

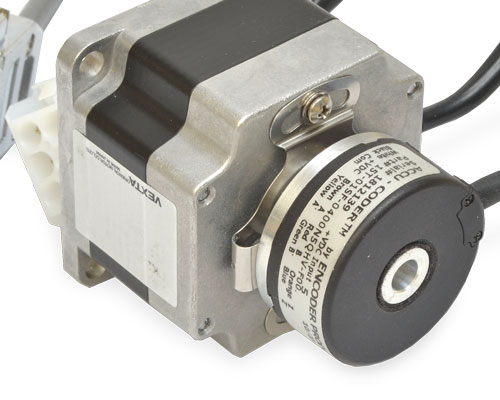

Several cycles per rev (CPR) options and shaft bores are available. In addition, we have single-ended optical rotary encoders that are more compact and used with Velmex XSlide™ Assemblies. They also can be attached to BiSlide® or UniSlide® Assemblies, if a rotary encoder is preferred.

Single-Ended vs. Differential Encoders

The majority of encoders offered by Velmex are differential encoders, which are preferred to increase the integrity of a measurement system. The Velmex VRO™ Readout is specifically designed to read these more robust encoders. Velmex does also offer a model of compact, modular, single-ended encorders which can interface with external electronics like the VRO. They are designed for less demanding applications.

| Encoder | Advantages | Disadvantages |

|---|---|---|

| Single Ended | • Lowest Cost | • Limited cable length • Vulnerable to electrical noise |

| Differential | • Long cable, lengths possible • High noise immunity • More robust |

• More costly than single ended encoders |

Encoder Styles

Velmex offers several types of encoders that are plug-in compatible with the VRO™ Enocder Readout. The encoders Velmex offers in its Ultra-Precision Measurement Systems are all incremental encoders. They include:

• Inductive Linear Encoders

• Magnetic Linear Encoders

• Rotary Encoders

|

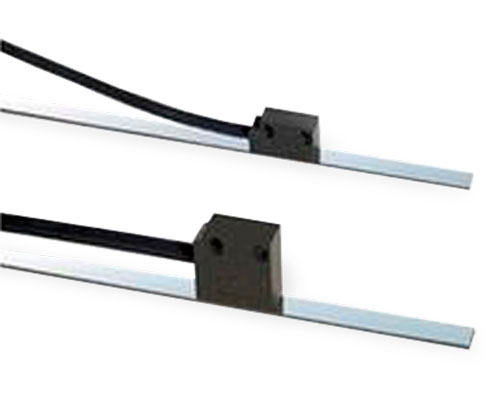

Inductive Linear Encoders – For manual and motorized BiSlide® linear stages and UniSlide® linear stages and elevating tables. (Cannot be used with A15 or A25 Series manual or MA15 or MA25 Motorized UniSlides.) |

|

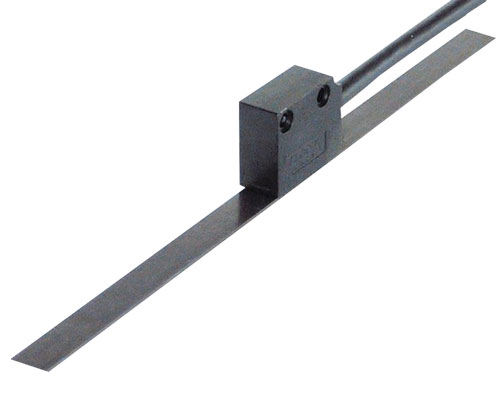

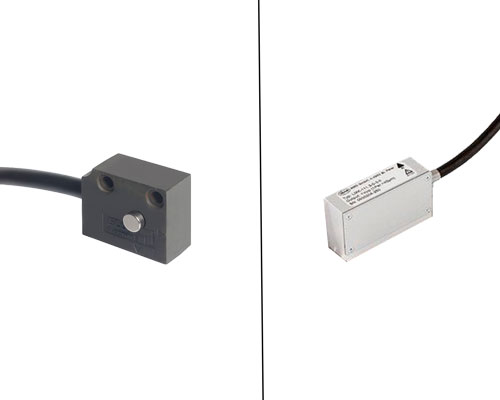

Magnetic Linear Encoder – For manual and motorized BiSlide and UniSlide linear stages. (Cannot be used with A15 or A25 Series manual or MA15 or MA25 Motorized UniSlides.) |

|

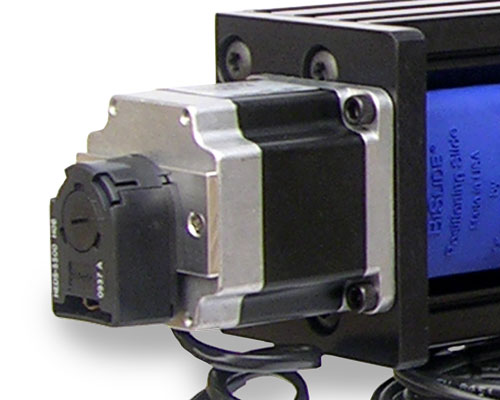

Single-ended Optical Rotary Encoder – For manual and motorized XSlides linear stages. Can also be used on manual lead screw driven UniSlide and BiSlide stages. (pictured on BiSlide stage.) |

|

Differential Optical Rotary Encoder – For use with a double-shaft stepper motor. Can be used on motorized UniSlide, BiSlide and XSlide stages and Rotary Tables. |

Velmex offers a readout for the Encoders. See the VRO™ Readout page for more information.

Encoder Specifications

| Encoder | Resolution | Accuracy | Repeatabilty | Head to Scale Clearance | |

| Inductive Scale |  |

0.001 mm | 0.010 mm / meter | 0.001 mm | 0.15 mm (0.05 to 0.36 mm) |

| Magnetic Scale |  |

0.001 mm | 0.025 mm / 100 mm |

+/- 0.01 mm | 2.5 mm (0.1 to 0.8 mm) |

| CPR (Cycles per Rev) | Accuracy | Bore Size | Size | ||

| Rotary Encoders |  |

100 CPR to 500 CPR* | Within 0.017° mechanical | 5 mm, 1/4", 3/8" | 1" Height, 1.5" Diameter |

*The resolution increments per rev are equal to 4x the CPR. (cycles per rev rating of the encoder) For example: 400 CPR = 1600 increments per revolution.

Options/Accessories for Encoders

Additional Options / Accessories available for Encoders include:

|

Replacement reader heads - available for the various encoders |

||

|

Assorted Cable Adapters - Various adapters are available to connect to computer via USB and to various brands of linear and rotary encoders. |

||

Encoder Cables - connects the encoders to the VRO to transfer position data. (Specified based on travel length.) |

|||

Additional standard and custom lengths are available for the linear encoder sensor tape from 3" to 228".

Encoder Documentation and Downloads

Applications and Examples of Encoders on Velmex products

These are examples of Velmex products. If you wish a similar product, please contact us with your specific application specifications (travel distance, payload, hours per day in use, resolution, speed range, etc.). You can use the Request Assistance form. |

Pictured in our gallery are examples that show various encoders the VRO connected to other Velmex products. Product and accessory offering is subject to change and availability.

| Example Key Code | Meaning | Example Key Code | Meaning |

|---|---|---|---|

| A | Manually Operated | M | Motorized |

| S | Standard | C | Custom Configuration |

| B | BiSlide | U | UniSlide |

| X | XSlide | R | Rotary Tables |

| T | XY Tables | TT | Turntables |

| E | Elevating Tables | FS | Fun Stuff (Ingenious, Cool, or Just out of the ordinary applications) |

Sorry, we don't have any images of our manual tables in a working application. Please check back later.

Examples of other Velmex products can be found on the Examples page or in the Examples section for each product.

Many questions can be answered by reviewing the "Features", "Model / Series", "Specifications", "Options / Accessories" and "Technical Documentation" sections for each product line. Additional FAQs about product comparisons, product construction, purchasing and shipping can be found on the company FAQ page.

Encoder FAQs

Can encoders be used with both the manually-operated and motorized stages?

Yes, encoders can be used to determine payload positions on Velmex slides and tables. We offer inductive and magnetic encoders for UniSlide® and BiSlide® linear stages and rotary encoders for the Rotary Tables and the compact XSlide™. You would also need a readout like the VRO™ to interpret the data being transmitted by the Encoder.

Why do you offer the variety of encoders that you do?

We've selected encoders that will deliver optimum performance for the slider / stage configuration and the application.

Why would the XSlide require a rotary encoder if it's a linear stage?

The design of the XSlide™ does not allow the use of a linear encoder. The carriage of the XSlide rides on the outside of the ways. A linear encoder would inhibit the movement of the carriage. Therefore, a rotary encoder fixed to the lead screw at the end of the XSlide is a better solution. They measure lead screw rotation with a typical resolution of 0.001" or 0.01 mm.

Can other digital encoder readout systems interpret the sensor readings from the encoders Velmex offers?

Yes, other readouts for incremental encoders can be used. However, the Velmex VRO™ has been specifically designed for high performance and ultra-precise digital position readings for the encoders used on Velmex stages.

Are there other ways to measure travel?

Yes, Velmex offers an number of options, in addition to the linear and rotary encoders, to measure travel. In most cases, these options would be used with manually-operated stages. They include:

• A lithograph scale attached to the base and index pointer attached to the carriage.

• A mechanical revolution counter

• Scale and vernier

• A graduated knob with precision grade lead screws (our most popular option)

• A micrometer head

To see which is measuring option is available for which Velmex product, check out that Product's Options and Accessories found on each Product Page.