|

|---|

Velmex Motorized Rotary Tables

For precise performance and continuous 360° rotational motion, choose from two series of powerful Velmex motorized Rotary Tables.

tab=0Overviewtab=1Featurestab=2Model / Seriestab=3Specificationstab=4Options / Accessoriestab=5Downloadstab=6Examplestab=7Troubleshooting / FAQs

Motorized-Operated Velmex Rotary Tables

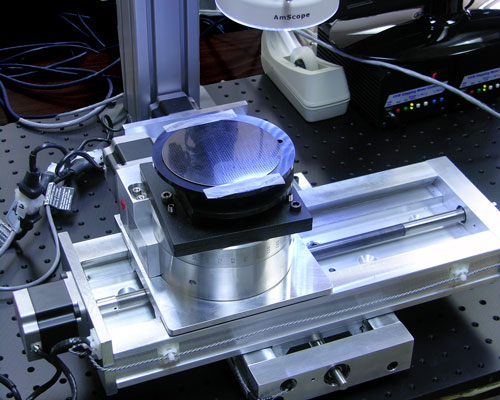

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating a payload.

The Rotary Tables use a rugged worm and gear drive design with a central rotating ball bearing to turn the payload. The mtoroized tables are also available in manually operated versions. The larger Rotary Table can support payloads up to 200 lbs. (90.7 kg) and the smaller can handle payloads up to 50 lbs. (22.6 kg.)

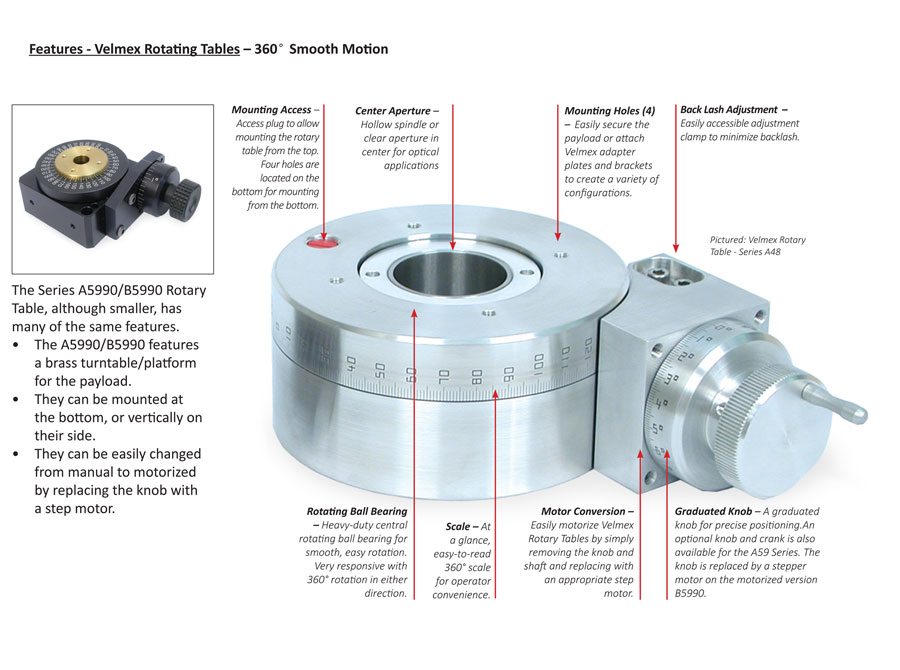

Velmex Rotary Table Features

Rotating Table Applications

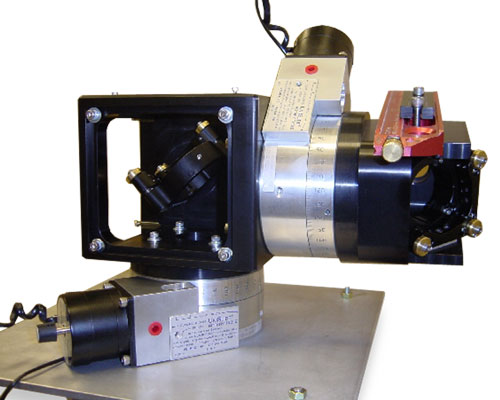

Typical applications for Velmex Rotary Tables include mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. The tables can also be used to tilt and pan.

Motorized Rotating Tables

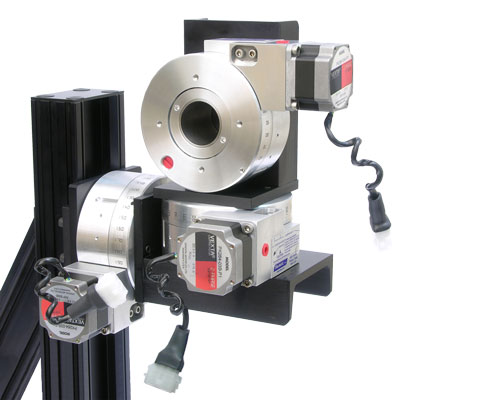

Rotary Tables –Motorized Rotary Tables rotate smoothly and easily around a single axis. They can be mounted either horizontally or vertically.

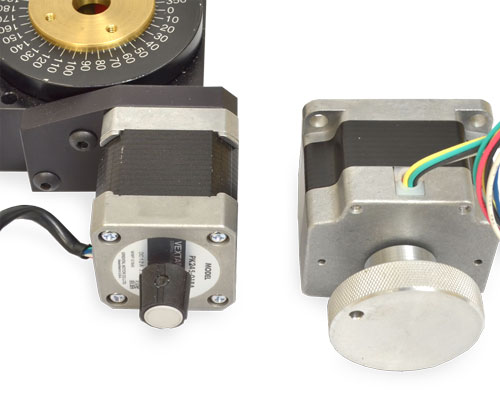

Manually-operated Velmex Rotary Tables can be easily converted to motorized positioners. Simply remove the knob and shaft and attach a stepper motor.

Part number information for each style can be found under Specifications at the end of the page.

Models:

|

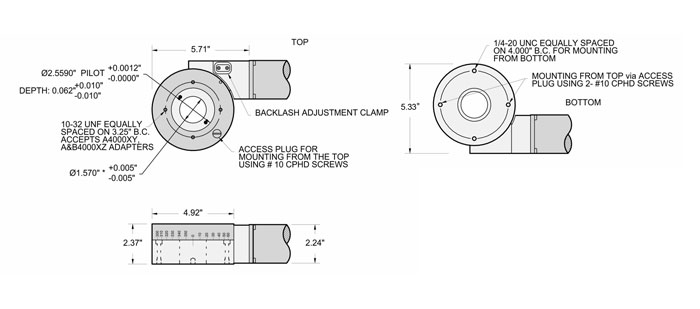

B48 Series – Three models with gear ratios of 18:1, 36:1 and 72:1. The B4800 Series has a load capacity up to 200 lbs. (90.7 kg.) horizontally and 25 lbs. (11.3 kg.) vertically. (The payload it can support vertically depends on the gear ratio. The lower the ratio, the less weight it can support.) Revolution time at 600 rpm ranges from 1.8 to 7.2 seconds, respectively. The series features a hollow spindle or clear aperture in the center. Aluminum finish is standard. |

|

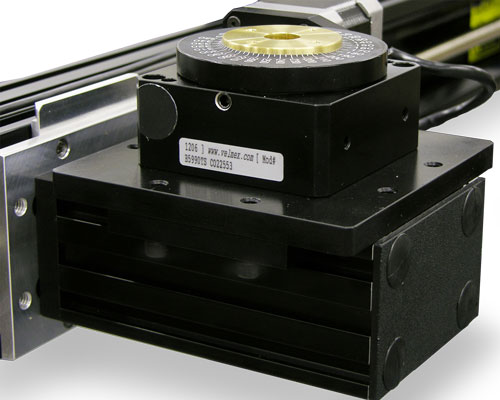

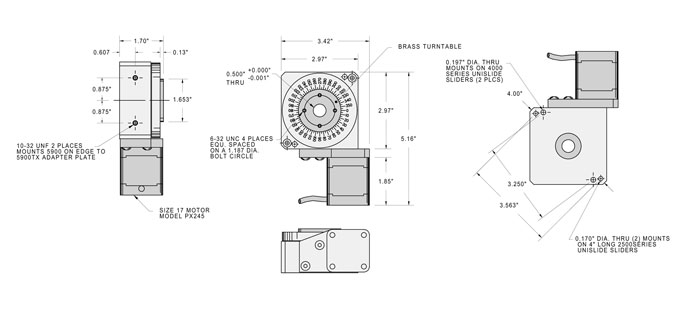

B59 Series – One model with a 90:1 gear ratio. The smaller B5900 can handle 50 lbs. (22.6 kg.) horizontally and 5 lbs. (2.3 kg.) vertically. Comes in a standard black anodized finish. Revolution time at 600 rpm is 9 seconds.

|

Velmex also offers manually-operated Rotary Tables. Also available manual Turntables.

Rotating Table Specifications

Factors such as size of the motor, size of the payload, in operation time, mounting direction/plane, etc. effect the actual capability of any assembly. Please contact Velmex Application Engineers to configure a system that will meet your exact requirements.

| Rotary Tables* | Gear Ratio | Diameter | Length w/o Motor | Height | Weight† | Clear Aperature Dia. | ||||||

| Series | In. | cm | In. | cm | In. | cm | lbs. | kg. | In. | cm | ||

| B4818TS |  |

18:1 | 5" | 12.7 | 8.28" | 21.0 | 2.37" | 6.0 | 5.5 | 2.5 | 1.57" | 4.0 |

| B4836TS | 36:1 | 5" | 12.7 | 8.28" | 21.0 | 2.37" | 6.0 | 5.5 | 2.5 | 1.57" | 4.0 | |

| B4872TS | 72:1 | 5" | 12.7 | 8.28" | 21.0 | 2.37" | 6.0 | 5.5 | 2.5 | 1.57" | 4.0 | |

| B5990TS |  |

90:1 | 1.65" | 4.2 | 4.77" | 12.1 | 1.70" | 4.3 | 2.7 | 1.23 | 0.5" | 1.27 |

† Weight of device without motor

* Motors sold separately.

| Rotary Table | Travel | Advance per 1 rev. on input | Increment per 400 step motor | Max input RPM | Speed (degrees per second at max. rpm) | Max input Torque | |

| Series | |||||||

| B4818TS |  |

0-360°+ | 20° | 0.05° | 600 | 200° | 150 oz-in |

| B4836TS | 0-360°+ | 10° | 0.025° | 600 | 100° | 150 oz-in | |

| B4872TS | 0-360°+ | 5° | 0.0125° | 600 | 50° | 150 oz-in | |

| B5990TS |  |

0-360°+ | 4° | 0.01° | 600 | 40.2° | 50 oz-in |

Maximum Dynamic Load Capacities of Rotary Tables

| Rotary Table | Horizontal Central Load | Cantilevered Load | Vertical Central Load | |||

| Series | lbs. | kg. | lbs. - in. | N-m | lbs. | kg. |

| B48 | 200 lbs. | 90.7 | 500 lbs.-in | 56.5 N-m | 25 lbs. | 11.3 |

| B59 | 50 lbs. | 22.6 | 20 lbs.-in | 2.26 N-m | 5 lbs. | 2.3 |

| Accuracy | 100 arc-second |

| Repeatability | 1 arc - second |

| Axial Runout and Radial Runout | Please contact Velmex |

| Operating temperature | 0 to 180° F (-18 to 82° C) |

| Properties of Velmex Stages | Information on stage composition, tolerances, wear and design for specialty applications. |

| Load Parameters | Definitions and parameters that effect the various load ratings. |

| B48 Series Rotary Table | ||

|

||

| B5990 Series Rotary Table | ||

|

||

Rotary Table Load

Represents the max load alowed on table in the positions depicted below. |

||

|

||

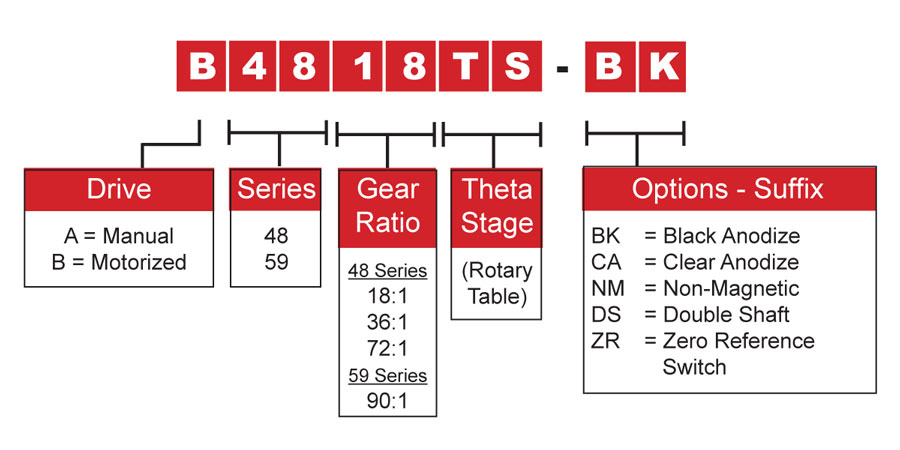

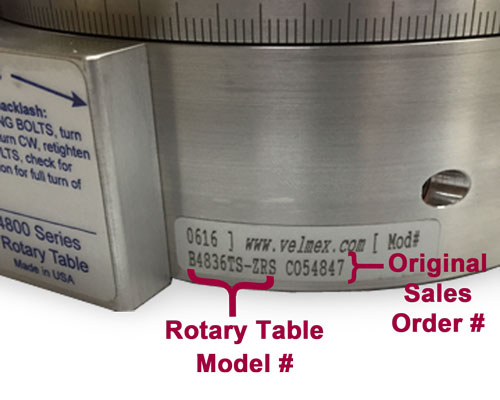

Rotary Tables have the same basic part number configuration. Additional suffixes are added for the options and accessories. You can determine the Rotary part number using the chart below. The number can be found on the side or end of any Velmex device you may already own.

|

The part number can be found on the side of the Rotary Table. |

|

|---|

Options/Accessories for Motorized Velmex Rotary Tables

Several options can be added to both the Rotary Tables and Turntables to make them more versatile and configurable with other Velmex products.

|

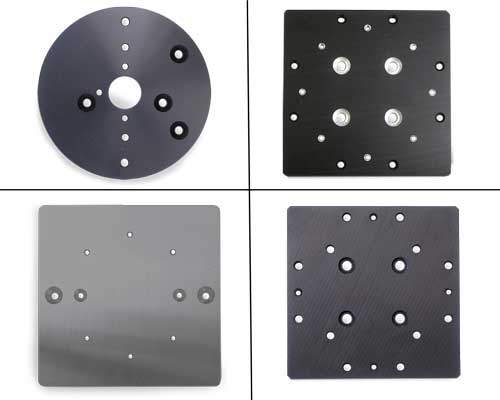

Rotating Table Adapter Plates –to mount Velmex Rotary Tables to other Velmex Assemblies either in horizontal or vertical positions. For more specifics and to see the plates and brackets in use on a Velmex stage visit the Rotary Tables Adapters page. |

|

MSPP-3 Adapter Plate – Used to mount Rotary Table (A48 or B48 Series) to BiSlide®. |

||

|

XZ Brackets – allow Rotary Tables to be positioned vertically. They can mount two Rotary Tables at right angles. The brackets can also be used as the base and support to mount other Velmex products or the payload on the Rotary Table vertically. |

|

A4001XZ-R Adapter Bracket – For mounting the A4800TS or B4800TS Rotary Tables. |

||

|

Platform shelf – A right angled bracket designed to be used with UniSlide® Elevating Tables. However, they also can be used with vertically mounted Rotary Tables to support a payload. The shelf can be inverted depending on the motion required. |

|

|

Magnetic Home Switch – A magnetic reed home switch sets and returns the carriage to home (starting) position. |

|

|

Limit Switches – Using two zero-reference (home) switches on a Rotary Table creates limits that restrict travel to a specific degree arc. |

|

|

Finishes – The A48 Series of Rotary Tables has a brushed aluminum finish. Optional finishes are available at an additional charge and include: |

|

• Black Anodizing, additional colors also available (pictured) |

||

|

Motorized / Manual Operation – It is possible, using a double shaft motor, to produce a Velmex rotary stage that can be manually operated or motor-driven. A shaft extension accommodates the either a Rogan or standard aluminum knob. It is also relatively easy to change out a manual knob for a motor on Velmex Rotary Tables. |

|

|

Encoders – For a high resolution position readout a rotary encoder and Velmex's VRO encoder readout can be mounted to Velmex Rotary Tables. VRO™ Encoder Readout – The VRO is compatible with all 5V incremental encoders. It can monitor one or two axis. Fully functional, it features automatic memory back-up of settings, sleep mode and self diagnostics. It's highly visible, wide-screen LED display makes it easy to view the positioning results. SEE: Velmex Controls on the Encoders and the VRO Readout for additional details. |

|

|

Motors and Motor-Controllers – A variety of motors are available to power Velmex Rotary Tables, most popular of which is the DC step motor. Step motors coupled with a motor controller like the Velmex VXM™ are a cost effective solution for accurate speed and precise incremental positioning. SEE: Velmex Controls on the Motors and the VXM Controller for additional details. |

|

CAD Drawings / Documents / Instructions

The majority of CAD drawings found in our Technical Library are Step (.stp) files. You will also see .dxf, .dwg, .sat and .pdf files. For .STP files, you may need to right click on the download button and save the "target" or "link". If you require a different format or cannot located the drawing you require, please contact us. Drawings are identified by the series/model part no. The number can be found on the side or end of any Velmex device you may already own.

For drawings for multi-axis configurations, please contact us. There may be an additional charge.

NOTE: Gear ratio variations are represented by a single drawing number.

| Click to open the section you need: | "Right Click" to download. |

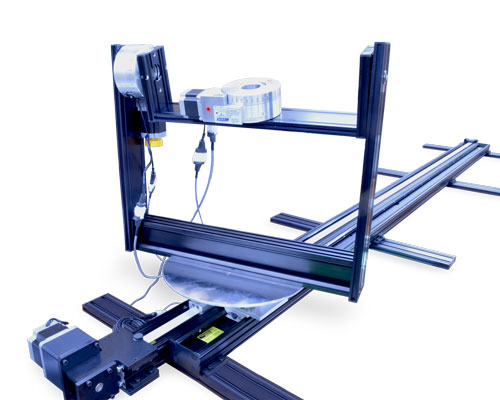

Velmex Rotary Table Applications and Examples

These are examples of Velmex products. If you wish a similar product, please contact us with your specific application specifications (travel distance, payload, hours per day in use, resolution, speed range, etc.). You can use the Request Assistance form. |

Pictured in our gallery are examples of configurations and systems using motorized Rotary Tables, along with configurations that also include other Velmex products. Product and accessory offering is subject to change and availability.

| Example Key Code | Meaning | Example Key Code | Meaning |

|---|---|---|---|

| A | Manually Operated | M | Motorized |

| S | Standard | C | Custom Configuration |

| B | BiSlide | U | UniSlide |

| X | XSlide | R | Rotary Tables |

| T | XY Tables | TT | Turntables |

| E | Elevating Tables | FS | Fun Stuff (Ingenious, Cool, or Just out of the ordinary applications) |

Velmex also offers manually-operated Rotary Tables. Examples of other Velmex products can be found on the Examples page or in the Examples section for each product.

Many questions can be answered by reviewing the "Features", "Model / Series", "Specifications", "Options / Accessories" and "Technical Documentation" sections for each product line. Additional FAQs about product comparisons, product construction, purchasing and shipping can be found on the company FAQ page.

Rotary Table Troubleshooting

First - always read the Users Manual.

| Symptom | Possible Cause | Possible Fixes |

|---|---|---|

| Manual Table: Knob will not turn. | Could have pushed the knob in causing it to bind. | Check position of knob. Pull out if possible. |

| Table will not turn. | Thumb lock may be active. | Check thumb lock to make sure it's not engaged. |

| Could have pushed the knob in causing it to bind. | Check position of knob. Pull out if possible. | |

| Backlash adjustment mesh set screw tightened too much. May need to be backed off. | The set screw needs to be adjusted per Mesh Adjustment directions. | |

| Load is mounted touching the optical aperture. You don't want any load touching the center aperture as it will gall or wear causing binding. | Remount load keeping it away from the aperture. | |

| Motor stalls or table is loud. | Backlash adjustment mesh set screw tightened too much. May need to be backed off. | The set screw needs to be adjusted per Mesh Adjustment directions. |

| Too much play in the table. | Backlash is excessive. | The set screw needs to be adjusted per Mesh Adjustment direction |

| Table is loud when operating. | If an older table and travel distance is minimal but continuous repetition, it may not have enough grease causing bearing wear. | Remove red plug in top of table and rotate until the worm gear is visible. Add grease if necessary. |

| Table grinds or catches when turning. | Check environment. If in a dusty application such as grinding, dirt may be accumulating inside and cause abnormal wear on the bearings. | May need to be returned for repair, at a nominal cost. |

| If a wet application, water accumulating internally may have caused the bearings to rust. | May need to be returned for repair, at a nominal cost. | |

| If the table will be operated in a wet, dusty or otherwise dirty environment where contaminates may accumulate, inform your Velmex Application Engineer in order to quote based on special needs. This could reduce added cost for future repairs. | ||

| Motorized Table: Motor stalls or table is loud. | Backlash adjustment mesh set screw tightened too much. May need to be backed off. | The set screw needs to be adjusted per Mesh Adjustment directions. |

| Motorized Table: Motor cannot be removed. | May not have used a motor with 2 flats set at 90° on the shaft. | Reset with a motor with 2 flats set at 90° on the shaft. See Rotary Table Motor Attachment. |

Do Velmex Rotary Tables need lubrication and how often?

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Do Velmex Rotary Tables have an open aperture?

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Can Velmex Rotary Tables be used in conjunction with other stages?

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

If you have questions about your specific application or want us to design a system incorporating Velmex Rotary Tables, please complete the Request Assistance form or call Velmex to speak to one of our Application Engineers.