|

|---|

![]()

Belt-Driven BiSlide® Assembly

The Velmex BiSlide Belt Drive Assembly is designed for long travel and high speed. The drive's high efficiency makes it an ideal solution for moving light loads at high speed and for continuous duty applications.

tab=0Overviewtab=1Featurestab=2Model / Seriestab=3Specificationstab=4Options / Accessoriestab=5Downloadstab=6Examplestab=7Troubleshooting / FAQs

This Belt-Driven BiSlide Stage is available in many standard lengths up to 220 inches (5.6 meters). It is designed to handle speeds up to 9.9 ft. (3 m) per second using direct drive motors and high powered controllers. This BiSlide configuration is only available as motorized.

The Velmex Belt-driven BiSlide system is assembled with a motor/gearbox mounted 90 degrees to the linear dovetail stage. The motor/gearbox couples to a stainless steel pulley which drives the steel reinforced precision timing belt. The maximum payload is 100 lb. (45.36 kg.)

Belt-Driven BiSlide® Features

Because the Belt-Driven BiSlide is a configuration of the linear Velmex BiSlide Assemblies, it has many of the same features and benefits found on the world-recognized BiSlide stages.

Belt-Driven BiSlide Style Options

Part number information for each style can be found under Specifications at the end of the page.

|

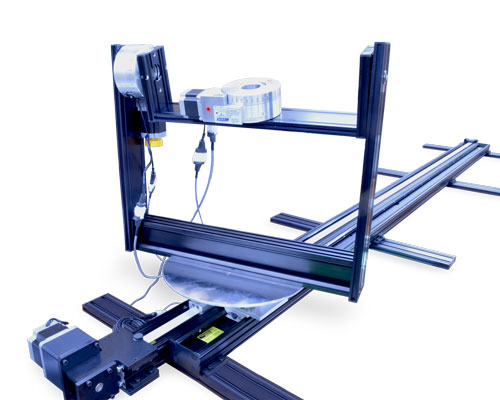

Single Axis - The Belt-Driven BiSlide Assembly is a motorized linear stage. It can be configured as a single axis or multiple axis system, including parallel-coupled. The standard Belt-Drive is available in travel distances from 10" to 220" in increments of 10". Style differences depend on the options added. (Pictured is a single axis Belt-Driven BiSlide) Please note: While we offer 10" and 20" Belt-driven BiSlides for special applications, travel lengths under 30" are not recommended for practical use for high speed or continuous duty applications. |

|

Parallel-Coupled - Pictured is an X axis Parallel-Coupled Belt-Drive BiSlide on a BiSlide frame system. The Y axis is another single linear Belt-Driven BiSlide. The Z axis is a lead screw BiSlide. See also Parallel-Coupled BiSlides. |

Please refer to either manually-operated or motor-driven BiSlide Assemblies for additional details, specifications and examples of other BiSlide models, series and styles.

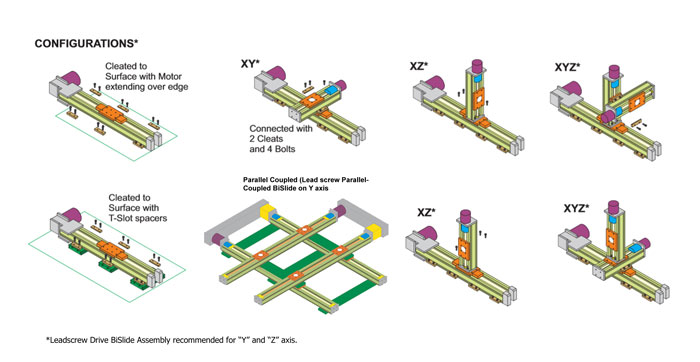

BiSlide Belt-Driven Configurations

The basic Belt-Driven BiSlide is a 1-axis linear stage. It can be configured a number of different ways and with multiple axes, incorporating lead-screw BiSlide Assemblies and using the BiSlide T-Slot and framing system. Two can be coupled together in parallel adding load capacity. See also Parallel-Coupled BiSlides.

A braking function should be included when operating the Belt-Driven BiSlide in a vertical application to prevent rapid descension of the payload. The Velmex's VXM™ Motor Controller has a braking option that can be used in this scenario.

|

Belt-Driven BiSlide® Specifications

Factors such as size of the motor, size of the payload, travel distance, mounting direction/plane, etc. effect the actual capability of any assembly. Please contact Velmex Application Engineers to configure a system that will meet your exact requirements.

| BiSlide® | Travel Distance‡ | Base Length | Slider Length | ||||

| Series* | Inches | cm | Inches | cm | Inches | cm | |

| MB10 – Belt Drive |  |

10"†† – 228" | 25.4 – 579.12 | 27.3" – 245.3" | 68.34 – 623.1 | 8" | 30.32 |

*Motors quoted separately. NEMA 34 units sold with .150" motor mounting coupling.

††While we offer 10" and 20" Belt-driven BiSlides for special applications, they are not recommended for practical use for high speed or continuous duty applications.

‡Standard travel distances available are in 10" increments.

| BiSlide® | Weight | Height | Width | ||||

| Series | lbs. | kg. | Inches | cm | Inches | cm | |

| MB10 – Belt Drive |  |

12.9 – 83.1 | 5.9 – 37.7 | 4.12" | 10.48 | 7.24" | 18.4 |

| BiSlide® | Dynamic Load | Static Load | Momentary Load | |||

| Load Capacity | lbs. | kg. | lbs. | kg. | lbs. | kg. |

| Normal Centered (maximum) | 100 lbs. | 45.36 | 200 lbs. | 90.72 | 300 lbs. | 136.1 |

| Thrust | 50 lbs. | 22.7 | 50 lbs. | 22.7 | 100 lbs. | 45.36 |

| Cantilevered | 500 lbs-in | 56.5 n-m | 500 lbs-in | 56.5 n-m | 500 lbs-in | 56.5 n-m |

|---|---|---|---|---|---|---|

| Coefficient of friction | 0.09 typical |

| Cantilevered Loads | Equivalent center load= (dxF/2) +F d= distance from center (inches) F= Load (lbs) |

| Minimum Input Torque Required | 75 in-oz |

| Repeatability | 0.0002" (0.005 mm) |

| Straight line accuracy | 0.0007"/ 10" (0.018mm/25cm) |

| Belt Pre-load Tension | 120 lbs (54.5 kg) |

| Pulley Pitch Radius | 0.6266" (15.9 mm) |

| Advance per turn | 100 mm ( 3.937") |

| Operating temperature | 23 to 158° F (-5 to 70° C) |

| Properties of Velmex Stages | Information on stage composition, tolerances, wear and design for specialty applications. |

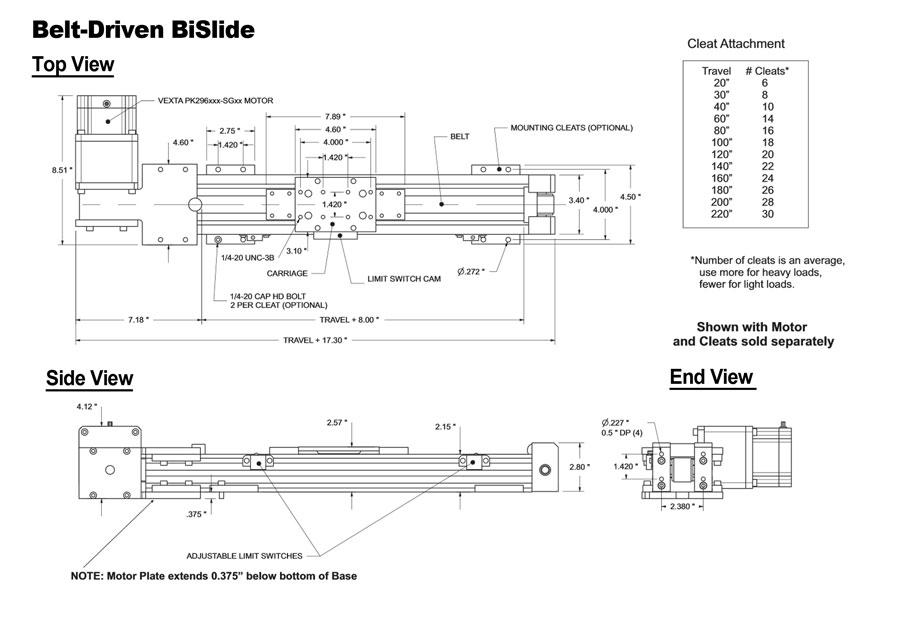

BiSlide® Dimensions |

||

|---|---|---|

|

||

| Carriage | ||

|

||

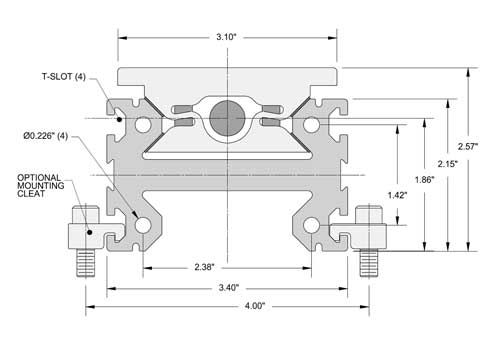

BiSlide Base Cross-Section

The slider / carriage (shaded area in the cross-section to the left) rides inside the guide ways. The 45 degree opposing ways give strength to carry the payload.

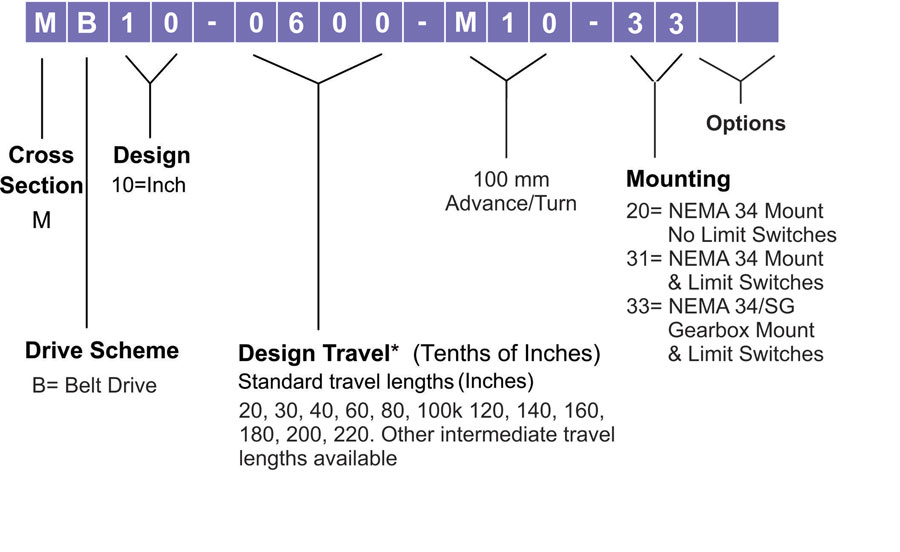

All BiSlides have the same basic part number configuration. The number varies with the series, the travel distance, the lead screw and the motor mountings. Additional prefixes and suffixes are added for the options and accessories. You can determine the BiSlide part number using the chart below. Belt-Driven BiSlide part numbers start with "MB".

|

Options/Accessories for Belt-Driven Velmex BiSlides®

See BiSlide Options and Accessories for more detailed information on the options and accessories that could be used on the Belt-Driven BiSlide Assembly. Here are a few of the more common ones.

|

Framing – The versatility of the BiSlide's modular design enables building of complex configurations. A variety of framing components can be combined and connected, disassembled and reassembled in alternate configurations to build BiSlide structures as needed. Included in the framing available are T-Slot Plate, I-Beam Base, T-Nuts, mounting bolts and other hardware. For more specifics and to see the framing components, including plates and brackets, in use on a Velmex stage visit the BiSlide Adapters page. |

|

|

Cleats - use BiSlide cleats to create rigid XY attachments, mountings for optical tables and attachments to other T-slot framing systems. The cleats are also used to secure BiSlides for longer travel distances and to support larger loads. Cleating Recommendations. |

|

MC-1 – Standard 1 hole cleat. Mounts the BiSlide to a frame / base / surface. Can be used to mount to other BiSlides in an XY, XZ or XYZ configuration. |

||

|

Encoders and VRO™ Encoder Readout – For a high resolution position readout an encoder and Velmex's VRO encoder readout can be mounted to the linear slides. An encoder, mounted directly to the slider gives a true and accurate reading eliminating lead screw and backlash errors. The VRO is compatible with all 5V incremental encoders. Fully functional, it features automatic memory back-up of settings, sleep mode and self diagnostics. It’s highly visible, wide-screen LED display makes it easy to view the positioning results. SEE: Velmex Controls on the Encoders and the VRO Readout for additional details. |

|

|

Outboard Adjustable Limit Switches – Mounted in a track on the side rib of Velmex BiSlide Assemblies to prevent over-travel. An optional third limit switch can be added between the two standard limits and used as an adjustable home switch. See Limits for more information. |

|

|

||

|

Motors and Motor-Controllers - A variety of motors are available to power Velmex UniSlides, most popular of which is the DC step motor. Integrated gear reduction motors are also available for economical operation. Servo motors are also used with the Belt-Drive BiSlide Assembly. Motors coupled with a motor controller like the Velmex VXM™ are a cost effective solution for accurate speed and precise incremental positioning. Gear motors, servo motors and high resolution step motors in both AC and DC can run Velmex BiSlides. SEE: Velmex Controls on the Motors and Velmex Controls on the VXM Controller for additional details. |

|

For .STP files, you may need to right click on the download button and save the "target" or "link".

| Click to open the section you need: | "Right Click" to download. |

The majority of CAD drawing found in our Technical Library are Step (.stp) files. You will also see .dxf, .dwg, .sat and .pdf files. If you require a different format or cannot located the drawing you require, please contact us. Drawings are identified by the series/model part no. The number can be found on the side or end of any Velmex device you may already own.

Velmex Belt-Driven BiSlide® Applications and Examples

These are examples of Velmex products. If you wish a similar product, please contact us with your specific application specifications (travel distance, payload, hours per day in use, resolution, speed range, etc.). You can use the Request Assistance form. |

Pictured in our gallery are examples of configurations for the Belt-Driven BiSlide, along with configurations that also include other Velmex products. Product and accessory offering is subject to change and availability.

| Example Key Code | Meaning | Example Key Code | Meaning |

|---|---|---|---|

| A | Manually Operated | M | Motorized |

| S | Standard | C | Custom Configuration |

| B | BiSlide | U | UniSlide |

| X | XSlide | R | Rotary Tables |

| T | XY Tables | TT | Turntables |

| E | Elevating Tables | FS | Fun Stuff (Ingenious, Cool, or Just out of the ordinary applications) |

Examples of other Velmex products can be found on the Examples page or in the Examples section for each product.

Many questions can be answered by reviewing the "Features", "Model / Series", "Specifications", "Options / Accessories" and "Technical Documentation" sections for each product line. Additional FAQs about product comparisons, product construction, purchasing and shipping can be found on the company FAQ page.

Do BiSlides need lubrication and how often?

Lubrication is important for motor-driven systems or wherever you want maximum life and the lowest friction. BiSlide Assemblies should be lubricated with Velmex BL-1 oil. Only a few drops are required to keep your slide running smoothly. The load and hours of use effect the amount and frequency of lubrication. Manual BiSlide assemblies require less frequent lubrication. See the user guide that came with your BiSlide for recommendations.

Can BiSlides be mounted together?

Yes, BiSlides can be mounted together in XY, XZ, XYZ configurations. Mounting BiSlide assemblies in multi-axis systems is easy using cleats. T-slot bases and frames can be added for more structure and to create application specific systems. They also can be combined with Velmex Rotary Tables and our other linear stages to make custom systems for a wide range of requirements. See BiSlide Options and Accessories for more information on the cleats and T-slot structuring.

How do I mount a BiSlide to my working surface?

BiSlides typically are mounted to any surface with the BiSlide cleats. The surface should be flat to avoid binding, operate smoothly and accurately. Steel or aluminum are recommended for the surface. For heavy loads, you start with 2 pair of cleats (4) and add a pair for every 5" in travel. Lighter loads would require fewer cleats.

How do you adjust the carriage fit on an BSlide?

Adjustments the carriage on a BiSlide may be necessary after break in period and less frequently thereafter. The Lead Screw Nut (StabilNut) has an adjustable mesh to minimize backlash. Carriage fit can be adjusted by tightening the bolts on the carriage surface. See the BiSlide Owners Manual for how and when to adjust.

How much weight can you lift vertically with a BiSlide Belt driven slide?

When used with a Velmex VXM™ controller you can lift up to 20 lbs. with the Belt Drive model. However, when using a BiSlide® Belt driven slide mounted vertically it should be used in conjunction with a "Fail-Safe-Brake" option to prevent rapid dropping. A VXM™ with braking option is offered. A servo system with similar braking option can lift up to 40 lbs vertically on the Belt Drive.

How do I increase the resolution on the Belt-Driven BiSlides?

Gear reduction motors are available that will increase the resolution on a Belt-Driven BiSlide, however, that will reduce the travel speed.

If you have questions about your specific application or want us to design a Belt-Driven BiSlide System for you, please complete the Request Assistance form or call Velmex to speak to one of our Application Engineers.