|

|---|

![]()

UniSlide® XY Tables

Velmex offers several pre-assembled UniSlide XY Tables to address customer requirements for indexing, scanning, fixturing, positioning and gauging. These Tables are designed using the proven UniSlide Linear Stages as a base. They are available in manual and motorized configurations.

tab=0Overviewtab=1Featurestab=2Model / Seriestab=3Specificationstab=4Options / Accessoriestab=5Downloadstab=6Examplestab=7Troubleshooting / FAQs

XY Tables

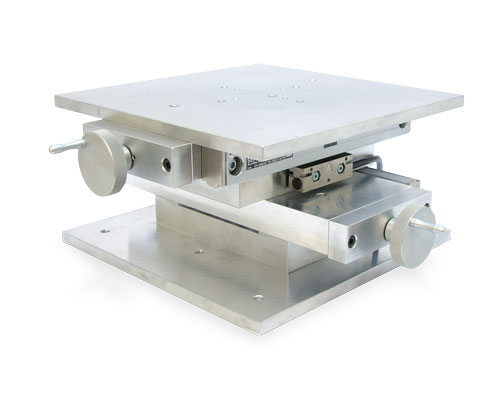

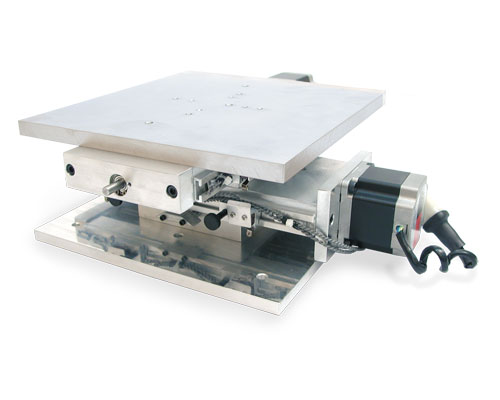

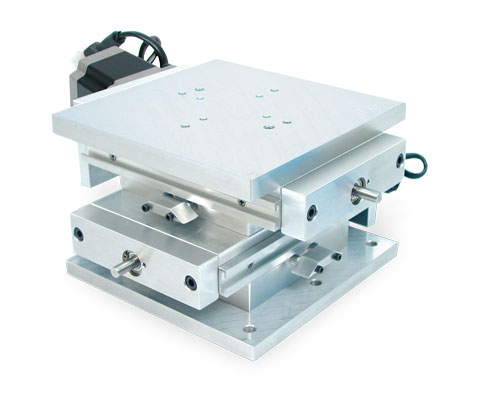

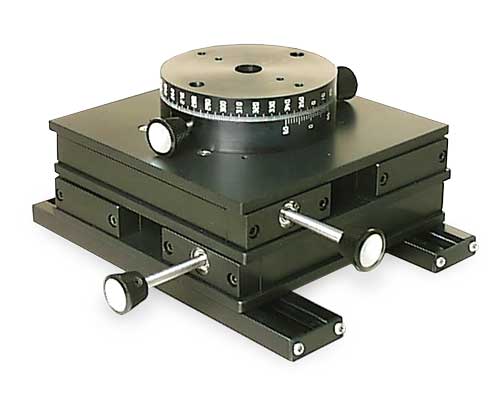

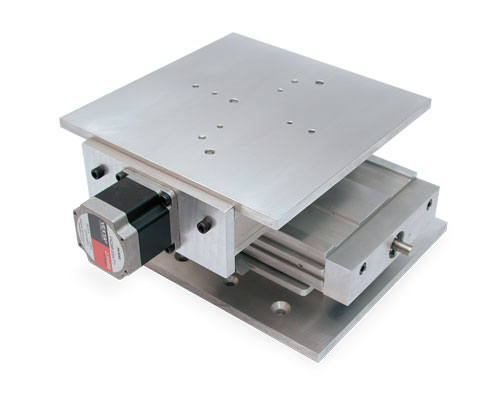

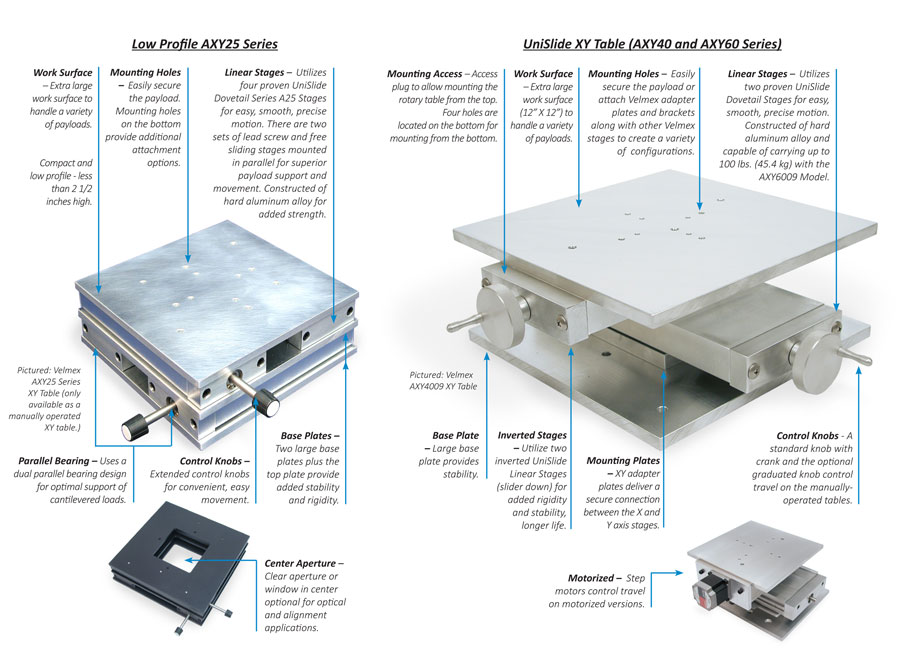

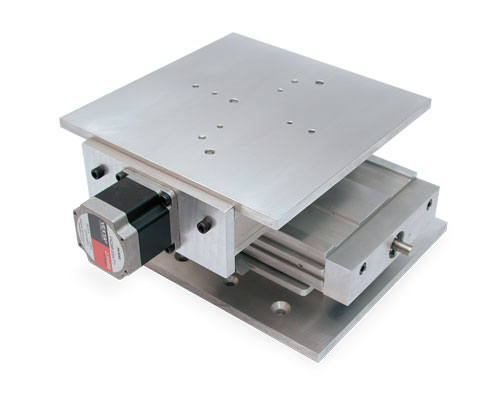

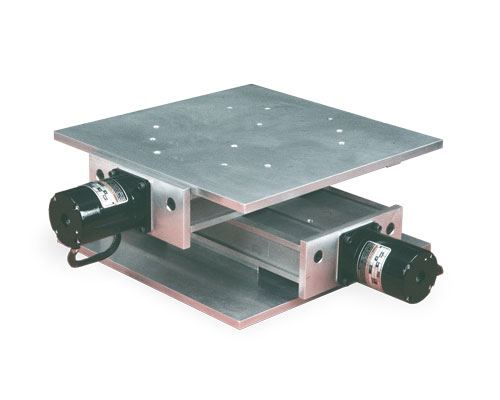

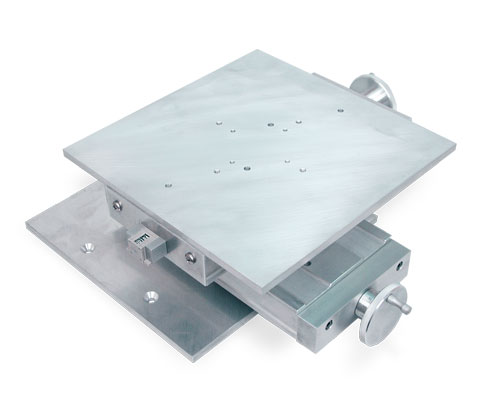

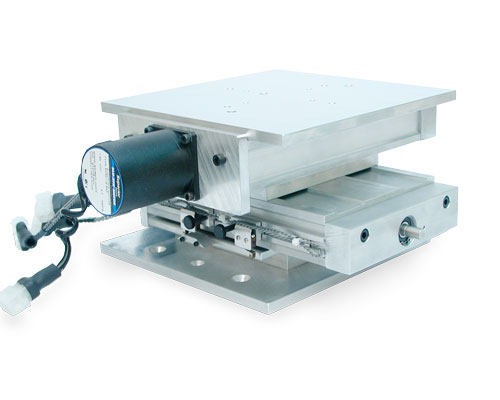

The large UniSlide XY Tables, Manual Series AXY40 and AXY60 and motorized Series MAXY40 and MAXY60 are designed with two A40 or A60 Linear UniSlide Assemblies or two MA40 or MA60 Assemblies, respectively, crossed and inverted with the carriages down for a more stable base. The tables also incorporate a large base for additional stability, two adapter plates to connect the X and Y axis slides, and an extra large work surface.

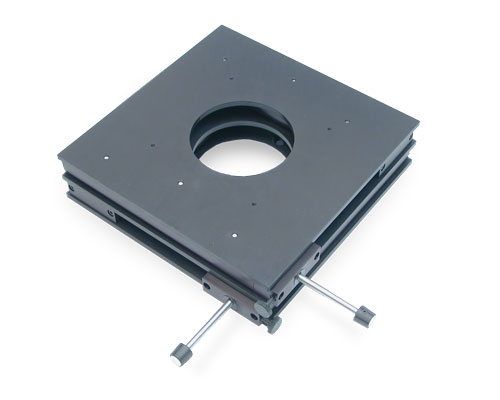

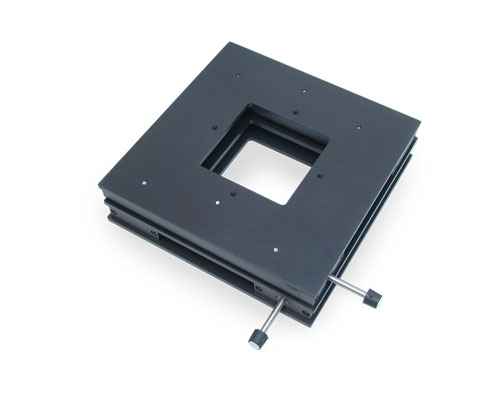

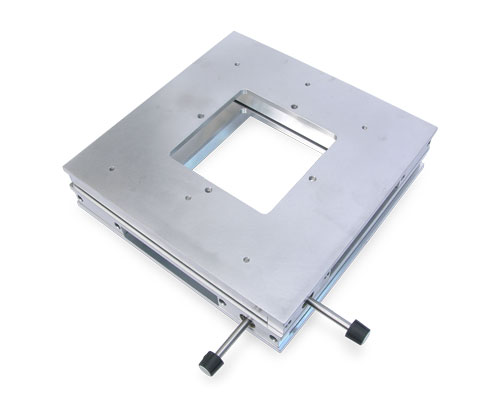

The lower profile and manual only AXY25 series is designed utilizing four linear A25 UniSlide Assemblies, two working in tandem to provide smooth movement in each direction. Virtually self-contained this table features a height of under 2 1/2 inches and delivers optimal rigidity and support for cantilevered loads.

All Velmex linear manual or motorized stages can also be combined in numerous XY configurations and, with the addition of adapter plates, used as an XY table.

XY Table Features

Manual XY Tables - Model / Series Options

|

AXY25 Series – Three low profile models with a travel range of up to 4" by 4" (10.2 cm x 10.2 cm). These models feature an unobstructed work platform. The models in this series can be purchased with or without a center window / aperture. Standard lead screw advance is 0.100"/revolution. |

|

• AXY2506W1 - 2" x 2" travel • AXY2509W1 - 3'' x 3" travel • AXY2512W1 - 4" x 4" travel |

||

|

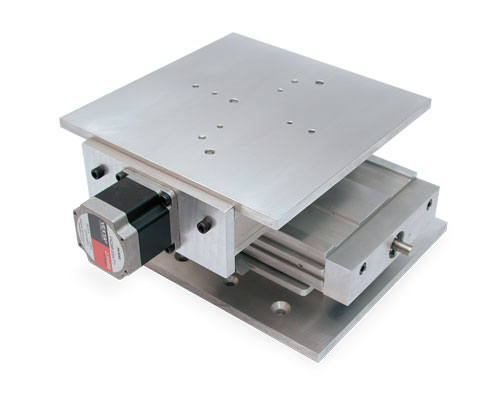

AXY40 Series – Two models with a travel range of up to 5" by 5" (12.7 cm x 12.7 cm). These models feature a large, unobstructed work platform. Standard lead screw advance is 0.100"/revolution. Other finer and coarser screws are available. |

|

• AXY4006W1 - 2" x 2" travel • AXY4009W1 - 5" x 5" travel |

||

|

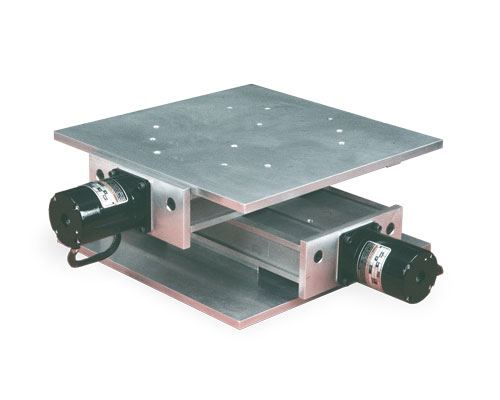

AXY60 Series – Three high profile models with a travel range of up to 9" by 9" (22.9 cm x 22.9 cm). These models feature a large, unobstructed work platform. Standard lead screw advance is 0.100"/revolution. Other finer and coarser screws are available. |

|

• AXY6009W1 - 3" x 3" travel • AXY6012W1 - 6" x 6" travel • AXY6015W1 - 9" x 9" travel |

||

Motorized XY Tables - Model / Series Options

|

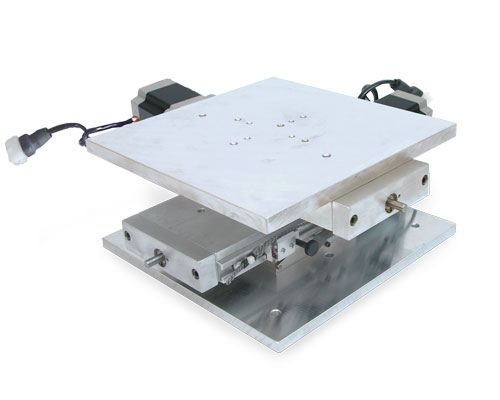

MAXY40 Series – Two medium profile models with a travel range of up to 5" by 5" (12.7 cm x 12.7 cm). These models feature a large, unobstructed work surface. Available in a variety of lead screw pitches. |

|

• MAXY4006XX* - 2" x 2" travel • MAXY4009XX* - 5" x 5" travel * XX represents lead screw pitch |

||

|

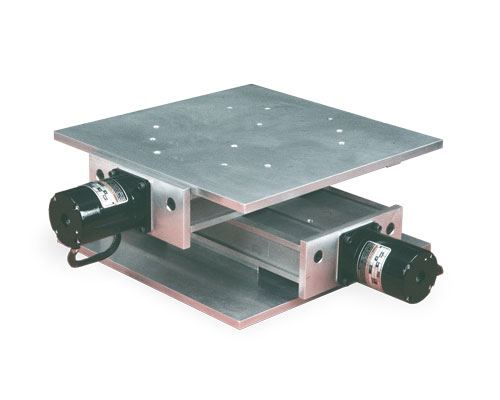

MAXY60 Series – Three high profile models with a travel range of up to 9" by 9" (22.9 cm x 22.9 cm). These models feature a large, unobstructed work surface. Available in a variety of lead screw pitches. |

|

• MAXY6009XX* - 3" x 3" travel • MAXY6012XX* - 6" x 6" travel • MAXY6015XX* - 9" x 9" travel * XX represents lead screw pitch |

||

XY Table Specifications

Factors such as size of the motor, size of the payload, travel distance, mounting direction/plane, etc. effect the actual capability of any assembly. Please contact Velmex Application Engineers to configure a system that will meet your exact requirements.

Manual XY Tables

| UniSlide® XY Tables | Travel Distance (W x L) | Base Plate Measurement | Maximum Envelope | ||||

| Series | Inches | cm | Inches | cm | Inches | cm | |

| AXY2506 |  |

2" X 2" | 5.08 X 5.08 | 6.75" x 6.75" | 17.15 X 17.5 | 13" x 13" | 33.02 x 33.02 |

| AXY2509 | 3" X 3" | 7.62 X 7.62 | 9.75" x 9.75" | 24.77 x 24.77 | 18" x 18" | 45.72 x 45.72 | |

| AXY2512 | 4" X 4" | 10.16 X 10.16 | 12.75" x 12.75" | 32.39 X 32.39 | 23.4" x 23.4" | 59.44 X 59.44 | |

| AXY4006 |  |

2" X 2" | 5.08 X 5.08 | 6" x 6" | 15.24 X 15.24 | 12.53" X 12.53" | 31.83 X 31.83 |

| AXY4009 | 5" x 5" | 12.7 X 12.7 | 9" X 9" | 22.86 X 22.86 | 18.53" X 18.53" | 47.07 X 47.07 | |

| AXY6009 |  |

3" X 3" | 7.62 X 7.62 | 9" X 9" | 22.86 X 22.86 | 17.03" X 17.03" | 43.26 X 43.26 |

| AXY6012 | 6" x 6" | 15.24 X 15.24 | 12" X 12" | 30.48 X 30.48 | 23.03" X 23.03" | 58.50 X 58.50 | |

| AXY6015 | 9" X 9" | 22.86 X 22.86 | 12" X 12" | 30.48 X 30.48 | 29.03" X 29.03" | 73.74 X 73.74 | |

| Manual UniSlide® XY Tables |

Maximum Load | Weight | Height | Minimum [Maximum] Aperture (Optional) |

|||||

| Series | lbs. | kg. | lbs. | kg. | Inches | cm | Inches | cm | |

| AXY2506 |  |

25 | 11.34 | 7.5 | 3.4 | 2.4" | 6.09 | 0.5" [1.5" sq.] | 1.27 [3.81] |

| AXY2509 | 12.5 | 5.69 | 0.5" [4.5" sq.] | 1.27 [11.43] | |||||

| AXY2512 | 17.7 | 8.03 | 0.5" [7.5" sq.] | 1.27 [19.05] | |||||

| AXY4006 |  |

60 | 27.22 | 8.7 | 3.95 | 3.78" | 9.6 | n/a | |

| AXY4009 | 25 | 11.34 | 13 | 5.9 | |||||

| AXY6009 |  |

100 | 45.36 | 24.5 | 11.11 | 5.5 | 13.97 | n/a | |

| AXY6012 | 60 | 27.22 | 32.7 | 14.83 | |||||

| AXY6015 | 25 | 11.34 | 36 | 16.33 | |||||

Motorized XY Tables

| UniSlide® XY Tables | Travel Distance (W x L) | Base Plate Measurement | Maximum Envelope | ||||

| Series | Inches | cm | Inches | cm | Inches | cm | |

| MAXY4006 |  |

2" X 2" | 5.08 X 5.08 | 6" x 6" | 15.24 X 15.24 | 12.53" X 12.53" | 31.83 X 31.83 |

| MAXY4009 | 5" x 5" | 12.7 X 12.7 | 9" X 9" | 22.86 X 22.86 | 18.53" X 18.53" | 47.07 X 47.07 | |

| MAXY6009 |  |

3" X 3" | 7.62 X 7.62 | 9" X 9" | 22.86 X 22.86 | 17.03" X 17.03" | 43.26 X 43.26 |

| MAXY6012 | 6" x 6" | 15.24 X 15.24 | 12" X 12" | 30.48 X 30.48 | 23.03" X 23.03" | 58.50 X 58.50 | |

| MAXY6015 | 9" X 9" | 22.86 X 22.86 | 12" X 12" | 30.48 X 30.48 | 29.03" X 29.03" | 73.74 X 73.74 | |

| Motorized UniSlide® XY Tables |

Maximum Load | Weight | Height | ||||

| Series | lbs. | kg. | lbs. | kg. | Inches | cm | |

| MAXY4006 |  |

60 | 27.22 | 8.7 | 3.95 | 4.125" | 10.48 |

| MAXY4009 | 25 | 11.34 | 13 | 5.9 | |||

| MAXY6009 |  |

100 | 45.36 | 24.5 | 11.11 | 5.5 | 13.97 |

| MAXY6012 | 60 | 27.22 | 32.7 | 14.83 | |||

| MAXY6015 | 25 | 11.34 | 36 | 16.33 | |||

Lead Screw Specifications for XY Tables

| Manual UniSlide® XY Tables |

Turns per Inch | Advance per Revolution | Screw Motion Type Code Letter – Standard Accuracy | Lead Screw Diameter |

| Series | ||||

| AXY25 | 10 | 0.100" | W1 | 3/8" |

| AXY40 | 10 | 0.100" | W1 | 3/8" |

| AXY60 | 10 | 0.100" | W1 | 1/2" |

| English Thread | ||||||

| Motorized UniSlide® XY Tables |

Turns per Inch | Advance per Revolution | Screw Motion Type Code Letter |

Lead Screw Diameter | Efficiency | |

| Series | – Standard Accuracy | – Precision Accuracy | ||||

| MAXY40 | 40 | 0.025" | C | P40 | 3/8" | 0.14 |

| MAXY60 | 40 | 0.025" | C | P40 | 1/2" | 0.14 |

| MAXY40 | 20 | 0.05" | B | P20 | 3/8" | 0.26 |

| MAXY60 | 20 | 0.05" | B | P20 | 1/2" | 0.26 |

| MAXY40 | 10 | 0.100" | W1 | P10 | 3/8" | 0.46 |

| MAXY60 | 10 | 0.100" | W1 | P10 | 1/2" | 0.46 |

| MAXY40 | 5 | 0.200" | W2 | P5 | 3/8" | 0.64 |

| MAXY60 | 5 | 0.200" | W2 | P5 | 1/2" | 0.64 |

| MAXY40 | 2.5 | 0.400" | W4 | P2.5 | 3/8" | 0.73 |

| MAXY60 | 2.5 | 0.400" | W4 | P2.5 | 1/2" | 0.73 |

| Metric Thread | ||||||

| Series | Turns per Metric | Advance per Revolution | – Standard Accuracy | – Precision Accuracy | Lead Screw Diameter | Efficiency |

| MAXY40 | 10 | 1 mm | K1 | Q1 | 10 mm | 0.15 |

| MAXY60 | 10 | 1 mm | K1 | Q1 | 14 mm | 0.15 |

| MAXY40 | 5 | 2 mm | K2 | Q2 | 10 mm | 0.33 |

| MAXY60 | 5 | 2 mm | K2 | Q2 | 14 mm | 0.33 |

| Repeatability | 0.00015" (4 microns) typical |

| Straight line accuracy | 0.003"(0.076 mm) over entire travel distance. Higher accuracy 0.0015" (0.038mm) available |

| Screw lead accuracy | 0.003"/10" (0.076 mm/25 cm) 0.0015"/10" available. Consult factory. |

| Operating temperature | 0 to 180° F (-18 to 82° C) |

| Properties of Velmex Stages | Information on stage composition, tolerances, wear and design for specialty applications. |

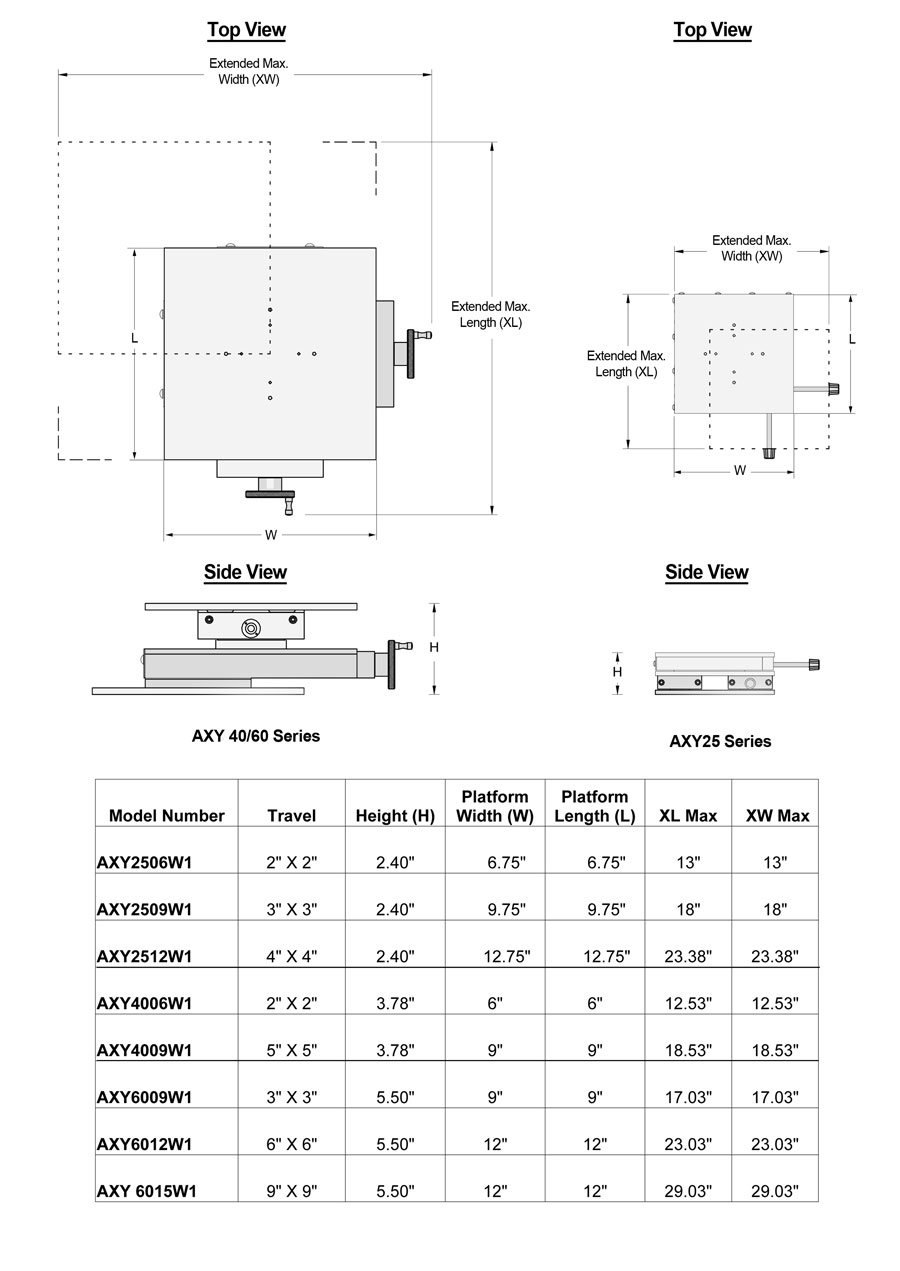

Basic Dimensions for Manual UniSlide XY Tables

Options/Accessories for UniSlide® XY Tables

|

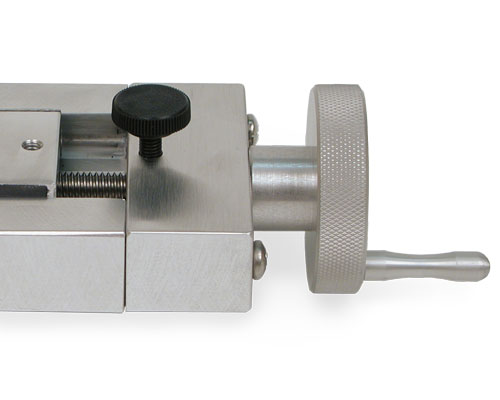

Alternative Knobs (Manual Series only) – The knob with a crank is standard on Velmex XY Tables Series AXY40 and AXY60. A Graduated Knob with the scale mounted on the top side of the base is available as an option on Series AXY40 and AXY60 Tables. |

|

|

Locks – (Manual Series only) - Are required on both axis. |

|

Thumbscrew-on-Lead-Screw Lock (-TL) (AXY40 and AXY60 only) – An easy method to affix the slider utilizing a simple thumbscrew on the lead screw at the end bearing block of each axis. Not available on AXY25. Slider Lock (-SL) (AXY25 only) – This lock is mounted at the mid-point on the base and is tightened to prevent slider movement. The lock is mounted on the slider/carriage on each axis. |

||

|

Revolution Counter (Manual Series Only) – A mechanical revolution counter provides a convenient 1/10 revolution increment count. Readouts in either 0.01" or 0.1 mm. |

|

|

Aperture (Manual AXY25 only) – Square window through center for a variety of optical and alignment applications including microscope and laser positioning, inspection, etc. . |

|

|

Finishes (Manual or Motorized Series) – Standard UniSlide Assemblies have a brushed aluminum finish. Optional finishes are available at an additional charge and include: |

|

• Black Anodizing, additional colors also available. (pictured) |

||

|

Encoders and VRO™ Encoder Readout (Manual or Motorized Series) – For a high resolution position readout an encoder and Velmex's VRO encoder readout can be mounted to most linear UniSlide assemblies. An encoder, mounted directly to the slider gives a true and accurate reading eliminating lead screw and backlash errors. The VRO Readout is compatible with all 5V incremental encoders. It can monitor one or two axis. Fully functional, it features automatic memory back-up of settings, sleep mode and self diagnostics. It's highly visible, wide-screen LED display makes it easy to view the positioning results. (Not available on all UniSlide models.) SEE: Velmex Controls on the Encoders and the VRO Readout for additional details. |

|

|

Limit Switches (Motorized Only) – Outboard adjustable and fixed end-of-travel limit switches are available as an option. |

|

Outboard Adjustable Limit Switches – Mounted on the side rib of Velmex UniSlide Assemblies, these switches can be used to stop travel, provide more stops than the standard two, over-travel a stop point, change speed or be active in only one direction. |

||

|

Motors – A variety of motors are available to power Velmex UniSlide Tables most popular of which is the DC step motor. Gear motors, servo motors and high resolution step motors in both AC and DC can run Velmex UniSlide XY Tables. SEE: Velmex Controls on the Motors for additional details. |

|

|

VXM™ Controller – Step motors coupled with a motor controller like the Velmex VXM™ are a cost effective solution for accurate speed and precise incremental positioning. SEE: Velmex Controls on the VXM Controller for additional details. |

|

NOTE: Lead Screw pitch variations are represented by a single drawing number.

For example - AXY2506W1 becomes AXY2506XXA "W1" lead screw pitch is standard with Velmex XY Tables, although other lead screws are available.

For .STP files, you may need to right click on the download button and save the "target" or "link".

| Click to open the section you need: | "Right Click" to download. |

Velmex UniSlide® XY Tables Applications and Examples

These are examples of Velmex products. If you wish a similar product, please contact us with your specific application specifications (travel distance, payload, hours per day in use, resolution, speed range, etc.). You can use the Request Assistance form. |

Pictured in our gallery are examples of configurations for both manual and motorized pre-assembled UniSlide XY tables. Product and accessory offering is subject to change and availability.

| Example Key Code | Meaning | Example Key Code | Meaning |

|---|---|---|---|

| A | Manually Operated | M | Motorized |

| S | Standard | C | Custom Configuration |

| B | BiSlide | U | UniSlide |

| X | XSlide | R | Rotary Tables |

| T | XY Tables | TT | Turntables |

| E | Elevating Tables | FS | Fun Stuff (Ingenious, Cool, or Just out of the ordinary applications) |

Examples of other Velmex products can be found on the Examples page or in the Examples section for each product.

Many questions can be answered by reviewing the "Features", "Model / Series", "Specifications", "Options / Accessories" and "Technical Documentation" sections for each product line. Additional FAQs about product comparisons, product construction, purchasing and shipping can be found on the company FAQ page.

UniSlide® Stage Troubleshooting

First - always read the Users Manual. Comments can also apply to UniSlide Pre-configured XY Tables.

| Symptom | Possible Cause | Possible Fixes |

|---|---|---|

| The carriage binds or will not move. | During mounting, the base may have been over-tightened or mounted to an irregular surface. This can distort the assembly, causing carriage binding. | Loosen screws and re-tighten to the proper torque. Mount the base using screws to the following torque: |

| • MA1500 Series 1 ft. lb. • MA or MB2500 Series 1 to 3 ft lbs. • MA or MB4000 Series 1 to 3 ft lbs. • MA or MB6000 Series 3 to 6 ft lbs. • MB9000 Series 3 to 6 ft lbs. |

||

| • Remount base to a flat surface. | ||

| Mounting non-flat plate or blocks to the carriage to hold the load can also distort the assembly, causing carriage binding. Anything attached to the assembly must be mounted flat to the carriage. | Re-mount load flat to the carriage or use a Velmex adapter plate designed to carry the load. | |

| Mounting screws holding payload to carriage may be too long and screwed into lead screw causing damage. | Re-mount load using a shorter screw length that does not extend past the carriage or use a Velmex adapter plate designed to carry the load. | |

| If the distortion is still present and the carriage still binds contact Velmex Application Engineers. The carriage and/or the lead screw may need to be replaced, or the Assembly may need to be returned on an RMA for repair. | ||

| There is some backlash in the carriage on a motorized UniSlide. | Some backlash maybe seen when the lead screw and carriage start to wear. | Adjust by tightening the Allen cap screw on the top of the drive nut. (CAUTION: Over tightening will increase friction, could stall the motor and cause increased wear.) |

| Use the "finger test" to check for binding. Grasp the lead screw on either side of the carriage and twist. If the lead screw can't be moved, the slide or the load may not be mounted properly or the mounting bolts are too tight. | ||

| There appears to be side play on a motorized UniSlide. | Objectionable side play can be reduced by tightening the adjustable expansion gibs that control the fit of the carriage. | Adjust the set screws located at the ends of the carriage. (CAUTION: Over tightening will increase friction, could stall the motor and cause increased wear.) |

| The limit switches do not appear to stop the carriage. | The limit switch collars must be set sufficiently distant from the ends of the Assembly to avoid collision with the end plate or limit switch cover. The carriage stopping distance is dependent on the speed just before limit switch activation. | Set the collar position for the maximum anticipated carriage speed. |

What comprise Velmex Pre-Configured XY Tables?

Velmex XY Tables are made of two identical Velmex world renown UniSlide® linear assemblies mounted in XY. The pre-configured Tables also have a much larger payload plate and base plate.

Do Velmex XY Tables use lead screws other than the "W1" with 0.100" per revolution?

Yes. Velmex Manually-operated XY Tables are standard with the W1 lead screw. Other lead screws are available as an option. Motorized XY Tables are available with most of Velmex's standard and precision accuracy lead screws.

Are there other types of XY Tables?

All of Velmex UniSlide®, BiSlide® and XSlide™ linear stages can be combined to make different size XY Tables to fit most any requirement. Thousands of different combinations are possible.

Do UniSlides need lubrication and how often?

Lubrication is important for motion systems or wherever you want maximum life and the lowest friction. UniSlide Assemblies can be lubricated with Velmex Lubriplate Aero®. Only a few drops are required to keep your slide running smoothly. The load and hours of use effect the amount and frequency of lubrication. See the user guide that came with your UniSlide for recommendations.

If you have questions about your specific application or want us to design system incorporating Velmex UniSlide XY Tables or another XY Table, please complete the Request Assistance form or call Velmex to speak to one of our Application Engineers.